The machine body has high strength, good rigidity, low loss, fast running speed, high machining accuracy and long service life;

Automatic lubrication system is adopted to provide lubrication for the equipment in fixed time and quantity to prolong the service life of rotating machinery;

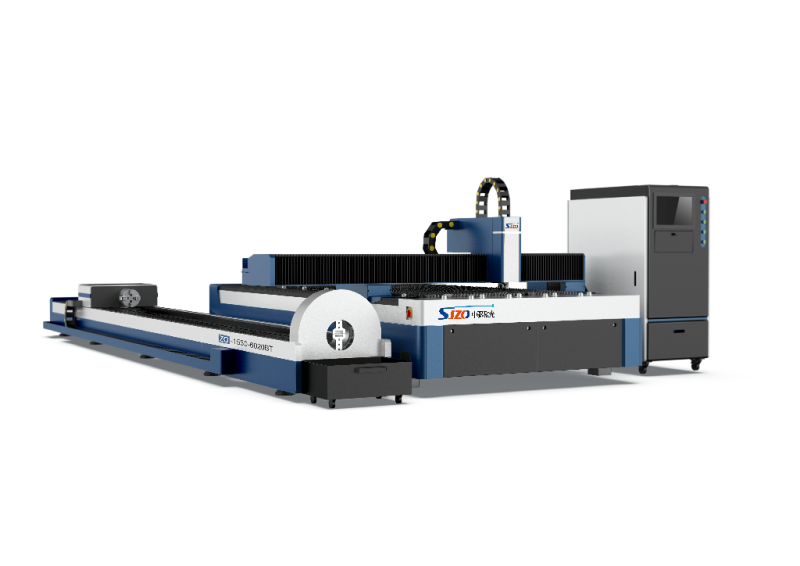

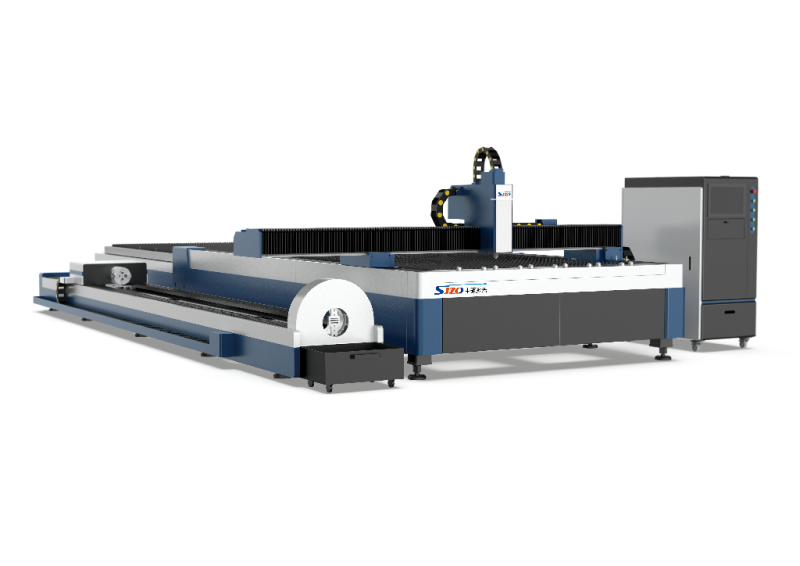

One machine dual-purpose, can meet all kinds of plate and pipe cutting needs; aluminum beam, light weight, high strength, corrosion resistance, reasonable transmission structure, stable dynamic performance; independent control cabinet, fully enclosed isolation, improve the service life of electrical components; timing and quantitative automatic lubrication system, effectively extend the service life of transmission machinery;

It adopts composite lens, built-in water-cooling structure, suitable for all kinds of systems and lasers; adopts high-quality carbon steel bed, with stable structure; aluminum cast beam, small density, light weight, anti-oxidation and anti-corrosion;

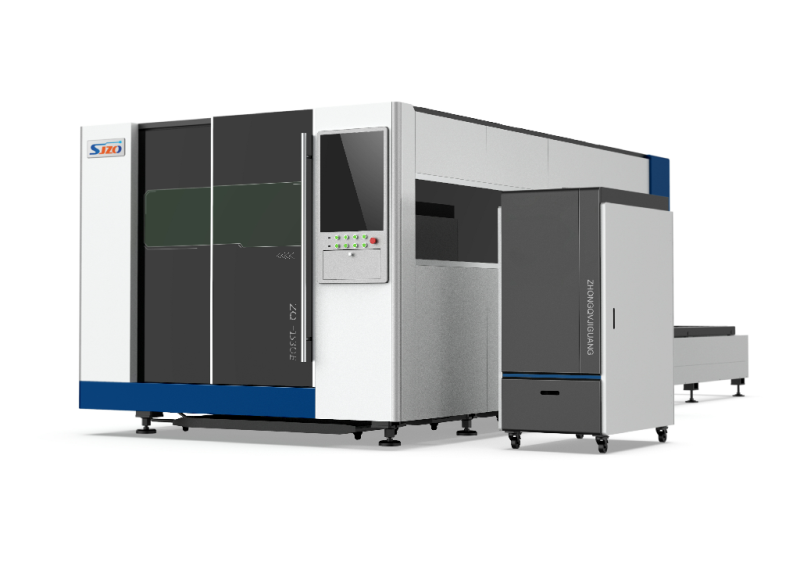

The high-speed parallel exchange platform is designed to complete the exchange within 10 seconds at most; it adopts high-quality carbon steel plate welding, stable bed structure, internationally famous guide rail, rack, motor reducer and other accessories; cast aluminum beam, light weight, anti-corrosion and anti-oxidation; automatic focusing system, with compound lens and built-in water-cooling structure;

One machine dual-purpose, can meet all kinds of plate and pipe cutting needs; aluminum beam, light weight, high strength, corrosion resistance, reasonable transmission structure, stable dynamic performance; independent control cabinet, fully enclosed isolation, improve the service life of electrical components; timing and quantitative automatic lubrication system, effectively extend the service life of transmission machinery;

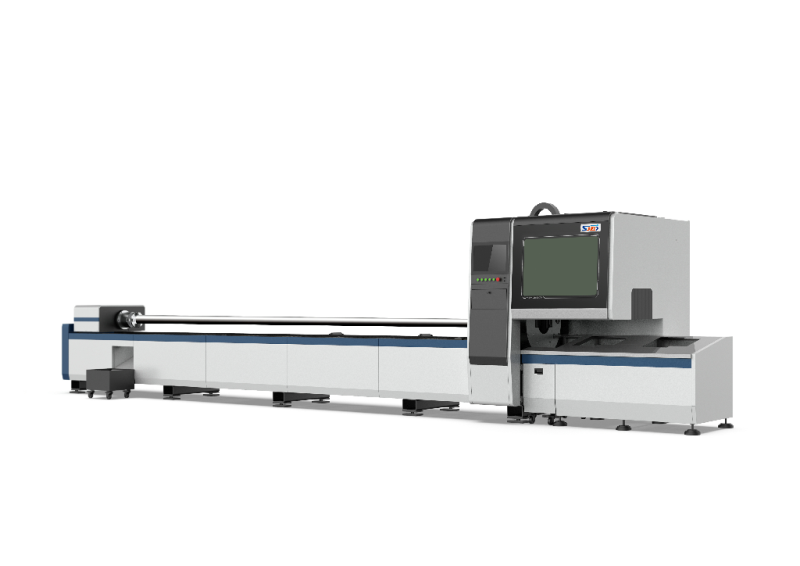

The intelligent pipe support design can solve the deformation problem in the long pipe cutting operation; the structure is simple, the installation is convenient, there is no need to match the pull rod, and the clamping is fast; the composite lens is used, the automatic focusing is not required, and the manual operation is not required; the built-in water-cooling structure, the automatic lubrication system and the timing and quantitative lubrication equipment are used to prolong the service life

Simple structure, easy installation, intelligent pipe support design, to solve the deformation problem of long pipe cutting operation; no need to match pull rod, clamping fast; use composite lens, automatic focusing, no manual; built-in water-cooling structure, automatic lubrication system, fixed time and quantitative lubrication equipment, prolong the service life of transmission machinery

It adopts industrial heavy-duty steel structure design, high-precision linear guide rail, wear-resistant; high-efficiency AC servo drive system, CNC pentahedron machining center processing, unified surface, hole, tapping and other processing technology one-time molding; Japan SMC intelligent gas group, dual gas path control, software automatic deployment; professional laser cutting head, imported optical lens, automatic focusing. Equipped with dual temperature and dual control professional chiller, the cooling speed is fast, and the photoelectric conversion is effectively improved; the new generation of fiber laser cutting, marking integrated system, compatible with a variety of software, can design any kind of graphics or text, instant cutting, simple, flexible and convenient operation;